10 Best High Temp Wheel Bearing Grease 2025 in the United States

Our technology thoroughly searches through the online shopping world, reviewing hundreds of sites. We then process and analyze this information, updating in real-time to bring you the latest top-rated products. This way, you always get the best and most current options available.

Our Top Picks

Winner

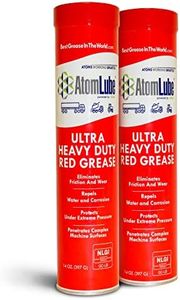

AtomLube Ultra Heavy Duty Red Grease, 2-Pack of 14 Oz. Tubes| Waterproof & High Temp Lubricant | Wheel Bearing Grease for Semi Truck Accessories

Most important from

1804 reviews

The AtomLube Ultra Heavy Duty Red Grease is a versatile high-performance lubricant designed for heavy-duty applications, particularly suitable for semi truck wheel bearings. It boasts an NLGI Grade of #2, indicating a good consistency for general-purpose grease applications. The grease is engineered to handle extreme pressures and high temperatures, making it ideal for demanding environments.

Its strong adhesive properties ensure it stays in place even under severe conditions, reducing the need for frequent reapplication. Additionally, it is waterproof and offers robust protection against corrosion and oxidation, thereby prolonging the life of the equipment it is used on. The product meets the NLGI GC-LB performance classification, which is a trusted standard for automotive wheel bearing and chassis grease.

The 2-pack of 14 oz. tubes offers a convenient supply for regular maintenance needs. This product appears to be a solid choice for those needing a durable and reliable grease for high-temp and heavy-duty applications, especially in the automotive sector.

Most important from

1804 reviews

TRIAX Spheron Grease, Super Heavy Duty, Red, High Temp, Ultra Tacky, Extreme Pressure, Virtually Waterproof; for 5th Wheel, Joints, Pivots, Wheel Bearings, and Chassis (2 Pack - 14 Oz Tubes)

Most important from

670 reviews

The TRIAX Spheron Grease stands out in the high-temp wheel bearing grease category due to its impressive temperature range and durability in extreme conditions. With a high operational temperature of -30°F to 450°F and a drop point exceeding 600°F, this grease is well-suited for high-temperature applications such as disk brakes and wheel hub bearings.

It offers exceptional shear stability and film strength, ensuring it won't break down under heavy lateral friction or severe loading, making it ideal for heavy-duty uses like semi-truck 5th wheels, U-joints, and pivot joints. Its extreme pressure rating of over 700 kg-f further emphasizes its robustness in demanding conditions. Additionally, the product's high tackiness and adhesion properties ensure it stays in place, even in high humidity or direct water contact, with less than 1% washout, making it virtually waterproof and resistant to corrosion.

The grease's GC-LB certification indicates its high quality and suitability for various applications, from wheel bearings to chassis lubrication. On the downside, the product's specific uses are geared more towards heavy-duty and trucking applications, which might be overkill for standard automotive needs. Furthermore, being a specialty product, it might come at a higher price point compared to more general-purpose greases. Nonetheless, for those needing reliable, high-performing grease in extreme conditions, the TRIAX Spheron Grease is a strong contender.